- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

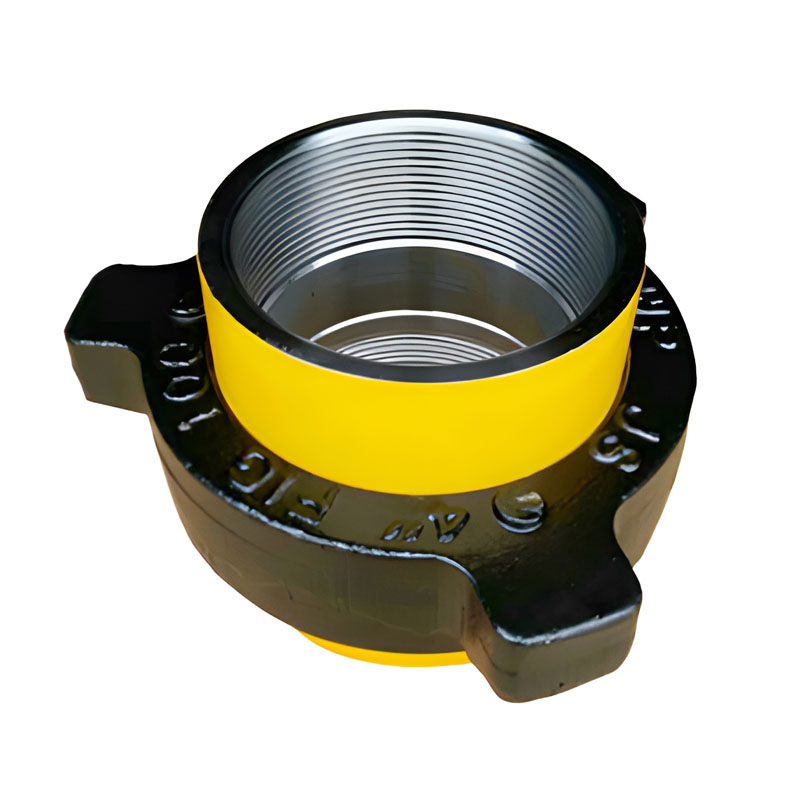

Oil Drilling Medium Pressure Union

Send Inquiry

Find a huge selection of Oil Drilling Medium Pressure Union from China at YITAI.

An oil drilling medium pressure union is a type of connector used in the oil and gas industry for joining and sealing high-pressure pipelines or equipment during drilling operations. It is specifically designed to withstand medium pressure levels, typically ranging from 1,000 to 6,000 pounds per square inch (psi).

This type of union consists of two male-ended threaded connections that can be screwed together to form a secure and leak-tight joint. The male ends are typically connected to the pipeline or equipment, and a gasket or sealing ring is placed between them to ensure a tight seal. The union can be easily disassembled and reassembled, making it convenient for maintenance or repairs.

Medium pressure unions are essential for maintaining the integrity and safety of the drilling system. They are used in various applications, including connecting drilling mud pumps, high-pressure hoses, blowout preventers, valves, and other components. These unions provide a reliable and secure connection, allowing for the smooth flow of drilling fluids and preventing leaks that could pose environmental and safety risks.

It’s important to note that specific designs and specifications of medium pressure unions may vary depending on the manufacturer and the intended application.

Application of oil drilling medium pressure union:

The union has a compact structure and is widely used in low pressure

killing pipelines, as well as in air, water, oil or steam applications

in medium pressure ranges for the requirements of occasions, the

available models are butt welded Sch.40.

| Nominal Pipe Size | Total Length | Radius Of Nut | Material Science | Weight | |||||

| Nut | Parts | ||||||||

| (in) | (mm) | (in) | (mm) | (in) | (mm) | (lbs) | (kgs) | ||

| 1 | 25.4 | 211/16 | 68.3 | 115/16 | 49.2 | SC/SF | CDB/SF | 1.75 | 0.8 |

| 1.25 | 31.7 | 27/8 | 73.0 | 23/8 | 60.3 | SF | SF | 2.37 | 1.1 |

| 1.5 | 38.1 | 27/8 | 73.0 | 23/8 | 60.3 | SF | SF | 2.37 | 1.1 |

| 2 | 50.8 | 315/16 | 84.1 | 229/32 | 73.8 | SF | SF | 2.25 | 2.4 |

| 2.5 | 63.8 | 41/16 | 103.2 | 311/16 | 93.7 | SF | SF | 10.0 | 4.5 |

| 3 | 76.2 | 43/8 | 111.1 | 37/8 | 98.4 | SF | SF | 15.25 | 6.9 |

| 4 | 101.6 | 413/16 | 122.2 | 5 | 127.0 | SF | SF | 20.0 | 9.1 |

| 6 | 152.4 | 65/8 | 168.3 | 67/16 | 163.5 | SF | SF | 44.5 | 20.2 |

More Details about pressure union

Hammer Union Hammer couplings are used for quick connections in cementing cars, oilfield applications, tank cars and rail cars, various manifolds and other high pressure equipment and piping. Working pressure 7Mpa~140Mpa (1000Psi~20000Psi) Couplings with different pressure levels are painted with different colors, and have different sizes, connection methods and pressure levels. The meter name is forged on the wing nut for easy identification and features a self-locking ACME thread design. All our standard connectors can be connected interchangeably with FMC.SPM products. Hammer joints have good mechanical and sealing properties. Reliable sealing performance The sealing ring adopts high-quality rubber composite material, which greatly improves the bearing capacity and sealing performance, and protects the connector from corrosion. In particular, they can operate in harsh weather conditions. They can be easily and conveniently assembled, fastened and replaced. They are very easy to use as they are self-aligning and do not require any special tools.Main Types:

Hammer Union type mainly consists of Figure50, Figure100, Figure200, Figure206, Figure207, Figure400, Figure600, Figure602, Figure1002, Figure1002 and Figure1502.

Fig 50.

These low pressure and suction hammer union of Fig50 are made from carbon steel. Available in 4" or 5" sizes in threaded & socket welded connection. These unions are suitable for 500 PSI wp.

Fig 100.

These low pressure hammer unions are ideal for manifold and applications where CWP does not exceed 1000 PSI.

Fig 200.

These hammer unions are best suited for medium pressure ranges involving air, water, oil & gas service for cold working pressure up to 2,000 PSI. Up to 4" no O-ring is used on the male sub. Beyond 4" size, an O-Ring is used on the male sub for sealing. The Figure 200 is a compact and economical hammer union, available with Threaded and ButtWeld ends.

Fig 206.

These hammer unions have an additional 'O' ring on the spherical surface of the male sub providing a leak proof seal. All dimensions of Fig200 & Fig206 are identical.

Fig 207.

Fig207 Blanking Caps and hammer unions are fully interchangeable with Fig200 and 206 hammer unions. For use where the blanking off at the end of a line is desirable. The cap is fitted with an 'O' ring to ensure a leakproof seal.

Fig 400.

These hammer unions are rigid in design and have all the three parts made of steel forgings. These hammer unions are best suited for manifold and line connections. Hammer unions from 3 inch through 8 inch sizes have O- rings for primary sealing. From 5" to 8" sizes C.W.P. is 2,500 PSI.

Fig. 600.

These hammer unions have wide range of applications including steam service and line connections. These unions are provided with a bronze seat in the female for the effective sealing and prevention of rust formation. Suitable for 6000 PSI CWP.

Fig 602.

These unions are recommended for manifold and line connections truck mounting and in mud services. These hammer unions have resilient lip-type seal for positive sealing and also protects secondary metal - to metal seal. Suitable for 6000 PSI.

Fig 1002.

These unions are designed for high pressure systems like choke and kill lines, cementing, acidizing, testing and truck mounted system. These hammer unions have a liptype seal made of nitrile rubber and subs made of alloy steel, suitable for 10,000 PSI.

Fig 1003.

These hammer unions protect against electrolytic action. There is no metal - to - metal contact between the subs. A resilent seal ring in the female sub provide additional sealing and protection from corrosion. Suitable for 2000 PSI CWP.

Fig 1502.

These hammer unions are widely used in cementing, manifold and other services where extra high pressure of 15,000 PSI CWP are encountered. There hammer unions are provided with replaceable seal ring.