- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

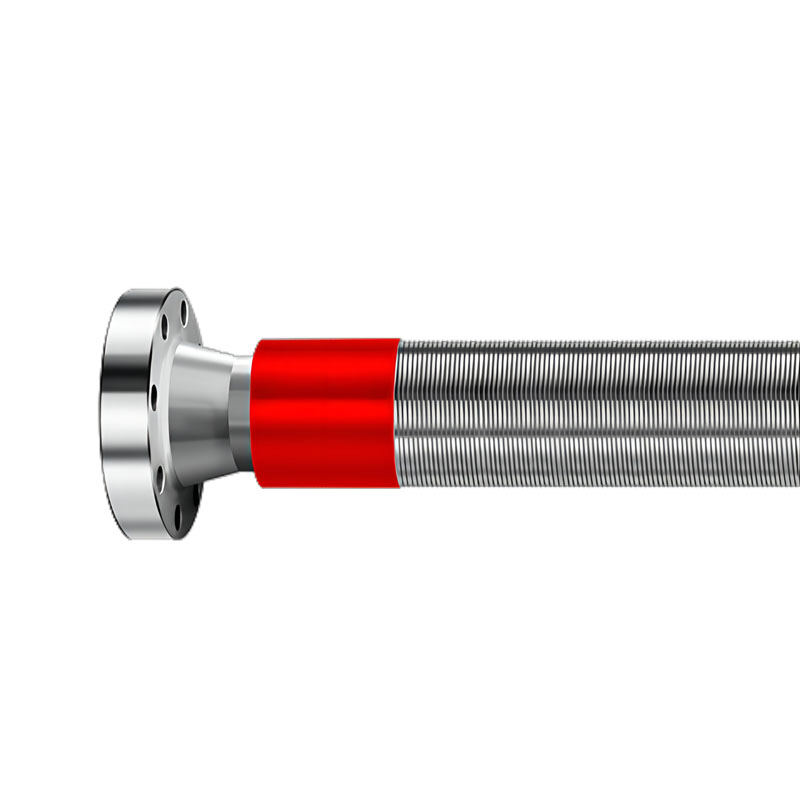

Armoured Hose

Send Inquiry

Introduction of Armoured Hose

An armored hose from YITAI, also known as a flexible metal hose with reinforcement, is a type of hose that is designed to handle extreme conditions and applications where high strength and resistance to physical and environmental factors are required. It is commonly used in industries such as oil and gas, chemical, and marine.

Armored hoses are constructed with a flexible metal tube or corrugated hose as the core element. The core material, usually stainless steel or another high-strength alloy, provides excellent resistance to pressure, temperature, corrosion, and external mechanical forces.

In addition to the core, armored hoses have additional layers of reinforcement, typically made of metal wire braids or interlocked metal bands. These reinforcement layers enhance the hose’s strength, durability, and resistance to various types of stresses, including internal pressure, external abrasion, torsion, and bending.

The external armor or protective covering is typically made of a metal braid or a strip-wound metal hose. This armor layer offers additional resistance against mechanical punctures, abrasion, and impact, providing protection to the core and reinforcement layers of the hose.

Armored hoses are commonly used in applications where flexibility and strength are essential requirements. They are used for the transportation of liquids, gases, or granular materials, including high-pressure fluids, corrosive chemicals, hot or cryogenic substances, and abrasive media.

Due to their robust construction, armored hoses are effective in demanding environments such as offshore platforms, petrochemical plants, chemical processing, military applications, and hydraulic systems where protection against extreme conditions and physical hazards is crucial.

YITAI Armoured Hose Parameter (Specification)

| pressure level |

I.D. (in.) |

O.D. (mm) |

W.P.(psi) |

P.P.(psi) |

Max B.P. (psi) |

Min B.P. (mm) |

Weight (kg/m) |

|

5000 |

2 |

95 |

5000 |

7500 |

11250 |

1000 |

7.9 |

|

3 |

126 |

5000 |

7500 |

1125 |

1200 |

13.1 |

|

|

4 |

163 |

5000 |

7500 |

11250 |

1400 |

18 |

|

|

5 |

193 |

5000 |

7500 |

11250 |

1600 |

27 |

|

|

7500 |

2 |

97 |

7500 |

11250 |

16875 |

1000 |

10 |

|

3 |

132 |

7500 |

11250 |

16875 |

1200 |

20.5 |

|

|

4 |

178 |

7500 |

11250 |

16875 |

1600 |

32 |

|

|

5 |

210 |

7500 |

11250 |

16875 |

1800 |

51.5 |

|

|

10000 |

2 |

105 |

10000 |

15000 |

22500 |

12000 |

12.3 |

|

3 |

123 |

10000 |

15000 |

22500 |

1600 |

30 |

|

|

|

160 |

10000 |

15000 |

22500 |

1600 |

35 |

|

|

5 |

180 |

10000 |

15000 |

22500 |

1800 |

62 |

|

|

15000 |

2 |

123 |

15000 |

22500 |

33750 |

1400 |

22 |

|

3 |

154 |

15000 |

22500 |

33750 |

1600 |

38 |

YITAI Armoured Hose Feature And Application

·Application:Flexible connecting pipelines of choke and kill manifolds, etc., deliver oil and gas mixtures containing hydrogen sulfide (H S) and other dangerous gases and various water-based, oil-based, foam kill fluids under high pressure.

·Inner glue layer:HNBR

·Inner diameter type: Full flow

·Enhancement layer:High strength super flexible steel wire or wire rope with multi-layer winding

·Outer glue layer:High temperature resistant and fire-resistant synthetic rubber (resistant to+704 ℃ open fire for 30 minutes)

·Temperature range:-29℃ ~+121℃

·Standards:API Spec. 16C FSL0 FSL1 FSL2 FSL3 | ABS

·Joint type:Integral union or integral flange